Ice makers have become indispensable in our daily lives. They help maintain a steady flow of ice, especially during hot summer days or parties. But when issues like overflow arise, it can disrupt the convenience and even cause damage to your surroundings.

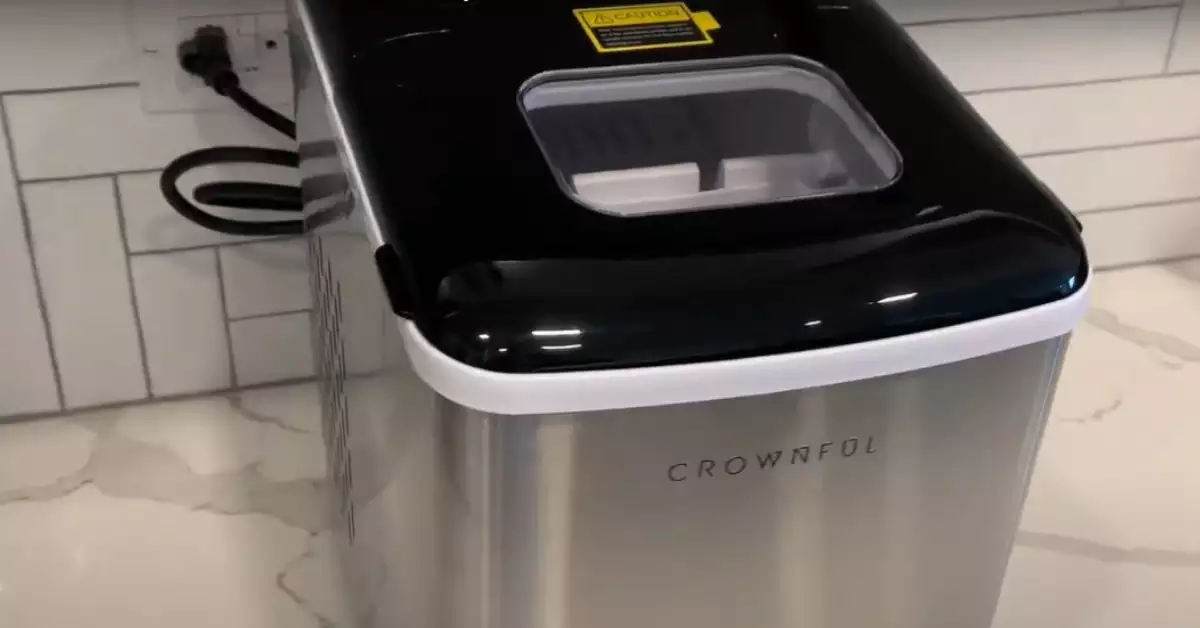

A common issue users face with their Crownful ice maker is overflow. Simply put, overflow occurs when the ice maker produces excess ice or water spills out of the machine, leading to potential hazards.

Crownful ice maker overflow can stem from a variety of reasons, ranging from simple blockages to technical malfunctions. Addressing these issues timely can prevent further damage and enhance the longevity of the appliance.

Basics of Ice Maker Operations

Ice makers operate on a fairly straightforward mechanism. Knowing the basics can give you an edge in identifying problems at their root.

How an Ice Maker Works

At its core, an ice maker:

- Takes in water through an inlet valve.

- Freezes the water in ice molds.

- Ejects the ice into a bin or tray.

Role of Water Inlet and Drainage

For seamless ice production:

- The water inlet must be free from obstructions.

- Drainage should be clear to prevent water accumulation.

Common Causes of Overflow

Overflow in an ice maker, especially in popular models like Crownful, can be a significant concern. The first step in remedying this problem is understanding the root causes. Here’s a deeper dive into common reasons behind this issue:

Blocked Water Inlet

The water inlet plays a crucial role in supplying water to the ice maker. Any disruption here directly affects the ice-making process.

- Sediments or Mineral Deposits: Over time, water, especially hard water, can lead to the buildup of sediments or mineral deposits. This accumulation can obstruct the water’s pathway, leading to erratic water supply and, consequently, overflow.

- Faulty Inlet Valve: The water inlet valve regulates the amount of water flowing into the ice maker. If it’s malfunctioning, it might allow more water than necessary, causing an overflow. Regular checks can ensure the valve operates optimally.

Malfunctioning Sensors

Modern ice makers employ sensors to detect various conditions and adjust operations accordingly.

- Ice Bin Detection: One of the most important sensors in an ice maker is the one that detects when the ice bin or tray is full. If this sensor is faulty, the machine won’t know when to stop producing ice, leading to overflows.

- Water Level Detection: Some ice makers also come equipped with sensors that detect the water level. A malfunctioning sensor of this kind might fail to signal the machine to stop water intake, causing overflow.

Faulty Timer Mechanism

The timer is the heart of the ice-making cycle, dictating how long each phase lasts.

- Importance in the Cycle: The timer controls how long the water inlet valve remains open, how long the water takes to freeze, and when the ice is released. Any irregularity in these timings can upset the whole cycle.

- Wear and Tear: Like all mechanical components, timers are susceptible to wear and tear. Over time, they might start malfunctioning, leading to shorter or longer durations than necessary, causing water or ice overflows.

Drainage Issues

The drainage system ensures excess water has a way out. Issues here can lead to water accumulation and eventual overflow.

- Blocked Drains: Just as sediments can block the water inlet, they can also clog the drainage system. Regularly flushing the system with clean water can help prevent such blockages.

- Improper Installation: Sometimes, the root of drainage issues lies in the installation. If the drain pipe is not set at the right angle or if there’s a kink, it can hinder water flow.

Troubleshooting Steps

An informed approach can help address and possibly resolve many of the common causes of overflow in ice makers.

Check Water Inlet

Ensure the smooth operation of the water inlet by:

- Visual Inspection: Check for any visible blockages or kinks in the inlet hose. A simple adjustment or cleaning can often remedy the problem.

- Water Valve Test: Manually operate the water inlet valve to ensure it’s functioning as expected. If it doesn’t open and close properly, consider replacing it.

Examine Sensors

Sensors are crucial for automated operations, and their optimal functioning is essential.

- Clean and Dust: Regularly clean sensors to ensure they can detect conditions accurately. Dust and dirt can sometimes interfere with their operations.

- Manual Testing: If you suspect a sensor isn’t working, test it manually. For instance, if the ice bin sensor isn’t working, try filling the bin with ice manually and see if the machine stops producing more ice. If it doesn’t, the sensor likely needs replacement.

Timer Mechanism Analysis

Ensuring the timer works accurately can prevent many ice-making anomalies.

- Monitor Cycle Duration: Keep track of how long one ice-making cycle lasts. If there’s a significant deviation from the standard duration (as mentioned in the user manual), it’s a sign the timer might be at fault.

- Consider External Factors: Sometimes, external factors like room temperature can affect the ice-making cycle. Ensure the ice maker is placed in a location as recommended by the manufacturer.

Drainage System Inspection

A clear drainage path ensures excess water doesn’t accumulate.

- Regular Checks: Inspect the drainage system for any visible blockages. Ensure the drain pipe is free from kinks and is positioned correctly.

- Flush with Clean Water: Periodically flushing the drainage system can help remove any budding blockages. It’s a simple preventive measure to ensure smooth operation.

Preventive Measures

While troubleshooting can address current issues, preventive measures ensure they don’t recur.

Regular Cleaning

Cleanliness can prevent many common ice maker issues.

- Internal Cleaning: At least once every few months, run a cleaning cycle. Use manufacturer-recommended solutions or mild detergents.

- External Wipe Down: Dust and dirt on external sensors can interfere with their operation. Regularly wiping down the machine can help.

Timely Replacement of Faulty Parts

Being proactive can save both time and money.

- Regular Inspection: Periodically inspect components like sensors, the timer, and the water inlet valve. If they show signs of wear or malfunction, replace them.

- Invest in Quality: When replacing parts, always opt for high-quality components, even if they might be a bit pricier. They often last longer and perform better.

Monitoring Water Supply and Pressure

Consistent water supply ensures smooth ice making.

- Check Water Sources: If you notice inconsistent ice sizes, it might be a sign of fluctuating water pressure. Check with local water suppliers if there are any ongoing issues.

- Install Pressure Regulators: If water pressure is consistently high or low, consider installing a pressure regulator to maintain optimal levels.

Solutions for Persistent Issues

If, despite all efforts, issues persist, it’s time to consider other solutions.

Consult a Professional

Sometimes, DIY fixes just don’t cut it.

- Expertise Matters: A professional can offer insights and solutions that might not be obvious to the average user.

- Regular Maintenance: Even if there’s no current issue, having a professional inspect the ice maker once in a while can prevent potential future problems.

Replacement vs Repair

It’s a tough call, but sometimes necessary.

- Evaluate Costs: If repair costs approach or exceed the price of a new ice maker, it might be more economical to replace the entire unit.

- Age of the Machine: Older machines are more prone to issues and might not be as energy-efficient as newer models. In such cases, replacement might be the wiser choice.

Frequently Asked Questions

Why is my ice maker producing tiny ice cubes?

This could be due to a restricted water supply, often caused by a blocked water inlet or a malfunctioning inlet valve.

How often should I clean my ice maker?

For optimal performance, it’s advisable to clean your ice maker every 3-6 months.

Can I use any cleaner for my ice maker?

No, it’s best to use manufacturer-recommended cleaners or a mild detergent. Harsh chemicals can damage the machine.

Conclusion

Crownful ice maker overflow, while a common issue, can be mitigated with timely interventions. Recognizing the signs and understanding the underlying causes are crucial for effective troubleshooting.

Maintaining an ice maker is not just about ensuring a steady supply of ice, but also about preserving the machine’s longevity and ensuring safety. With the right knowledge and approach, you can ensure that your Crownful ice maker serves you efficiently for years to come.